Sun drying is the oldest food technology still in use today. (I believe it predates fire, but hey, I could be wrong.) It’s not too common these days, since cheap electricity allows us to dry things much more quickly than the sun does. But sun drying can produce some incredibly flavorful foods including some of our favorites like sun dried tomatoes, couscous, salt, and rice. And it can do so in an incredibly environmentally friendly way.

The first sun dried foods were a product of necessity.

Removing moisture helps to preserve food, and also made it lighter to carry, two reasons why the nomadic Berber peoples of North Africa started sun drying foods thousands of years ago. By processing wheat into sun-dried couscous they were better able to have a ready food supply, even if they had a year or two of bad crops. The fact that slow sun drying can also produce a lot more flavor must have been a bonus; the sun dried couscous made by the Mahjoub family in Tunisia is toasty, wheaty, and way more flavorful than any other couscous I’ve tried. The sun dried garlic spread that the Mahjoubs make is likewise deeply flavorful. The time it takes for the garlic to dry in the sun concentrates its flavor, enhancing its natural sweetness—the same sort of effect you get from roasting a head of garlic in the oven.

That intensity of flavor is a common theme amongst sun dried foods. Marash pepper from Turkey is a prime example. After being harvested in August, shiny red peppers are laid on white muslin sheets to dry in the sun for a week. The type of pepper used is prized because its thin flesh can dry fairly quickly; thicker peppers end up with a tougher texture. After drying, the stems, seeds, and white interior flesh of the peppers are removed, which reduces the heat level but maintains the flavor. The result is a burgundy pepper flake with a deep, roasted chile flavor that lasts and lasts without ever getting too hot.

Of course, taking several days to dry a product in the sun has its risks. What if it rains?

That’s a concern for heirloom rices from the Philippines, like Kalinga Unoy or Tinawon White, which are sun dried despite being harvested during the rainy season. The drying process takes three full days of eight hours of sunlight. Sometimes it can take a few weeks to get this much sun when the weather is cloudy or wet. Whenever the sun isn’t out, all of the rice must be moved into a granary for safe keeping. Even when the weather is nice, the farmer will tend and turn their rice regularly to ensure even drying. Most producers these days dry their rice by blasting it violently with air, but the more time the grain spends in machinery the greater the chance is that it’ll be damaged. Gentle sun drying helps to maintain the natural sweet and nutty fragrance of the rice. For vibrantly colored rices like rusty red Kalinga Unoy, sun drying also helps to set the color of the rice bran.

This ancient technology is up-to-the-minute environmentally friendly.

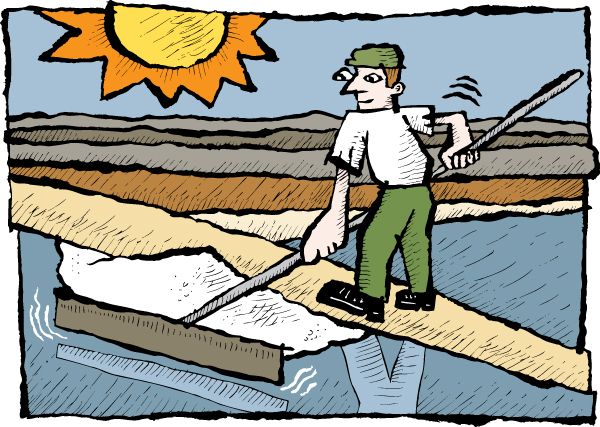

The counterintuitive thing about sun dried foods is that, even when they’re shipped to us from the other side of the world, they can be more environmentally friendly than local foods that rely on more energy-intensive methods to create. Take salt, for example. To make salt here in Michigan we have to mine it with heavy machinery (that’s how the Kosher brand salt you see at grocery stores is made—it’s mined just north of Ann Arbor). To make it in foggy coastal places like Wales you have to boil it out of the sea water, which takes a tremendous amount of fossil fuel. But on the sunny Southern coast of Portugal or along France’s Brittany coast, salt can be harvested from shallow pools of sea water that evaporate in the sun. The salt is raked by hand and the only machine you’ll spot is a conveyor that piles it high for storage until it’s shipped to us.